As the digital wallcovering trend continues to climb, more and more architects and designers are specifying Type II wallcovering (pronounced Type 2).

Type II wallcoverings are often used in high-traffic areas or in commercial spaces, such as hotels, restaurants, hospitals, office interiors, and more.

What does Type II mean?

The Type II definition has changed throughout the years and luckily there is a recognized governing body that maintains these standards, called the WA or Wallcovering Association.

Recently the WA published a new definition of TYPE II called the WA-101. This standard is intended for “polymer coated fabrics” which includes PVC and Olefin wallcoverings like DreamScape.

Along with the new definition is a Sustainability Standard called the NSF-342. DreamScape products follow these modern standards. Many competitive products do not. More information on WA-101 and the NSF-342 can be found here.

A true Type II wallcovering has the following characteristics:

- a weight requirement of 20 ounces per 54″ linear yard.

- made of thicker, more durable materials, such as vinyl or canvas

- can withstand more wear and tear than standard wallcoverings

- resistant to fading, staining, and damage from abrasion

- easier to clean and maintain than standard wallcoverings

What tests are performed on wallcoverings to qualify for Type II certification?

Contained within the WA-101 is a large list of tests. There are several durability tests, such as scrub, tear, and stain. There is also a safety component that limits the flammability of the product as well as limits the amount of smoke that should be released during a fire.

Here are the 12 physical tests performed to qualify for TYPE II:

- Breaking Strength | Test Method

- Tear Strength (1) | (ASTM D-751 – Grab Method

- Coating Adhesion | ASTM D-751 – Pendulum Impulse Method

- Colorfastness to Light (2) | ASTM D-751

- Blocking | Federal Test Method Standard 191A – Method 5660

- Crocking | Federal Test Method Standard 191A – Method 5872

- Cold Crack Resistance | Federal Test Method Standard 191A – Method 5651-b

- Heat Aging (3) | Paragraph 7.1.2

- Shrinkage | Federal Test Method Standard 191A – Method 5850

- Stain Resistance | (4) ASTM D-1308

- Washability | ASTM F793

- Scrubability | ASTM F793

How do I know if my wallcovering is Type II?

Some products in the digital market claim to be “commercial-grade,” or Type II even if they have not passed the tests in the table above.

Old standards did not define weight and some companies outside the wallcovering industry could be unaware of the WA-101 modern definition. And perhaps some are trying to take advantage of misinformation.

However, there is no TYPE II police, and you will need to determine if your wallcovering is in fact truly a Type II. Here are a few suggestions to determine if the product you are considering meets the :

- Ask if the product meets all components of the WA-101 specification

- Ask if the product meets the new Sustainability Standard NSF 342

- Check the manufacturer’s product specifications.

- Ask to see results from the manufacturer

- Look for testing certificates from a 3rd party lab to assure the 12 test types above are covered

Can digital prints pass TYPE II without a protective coating?

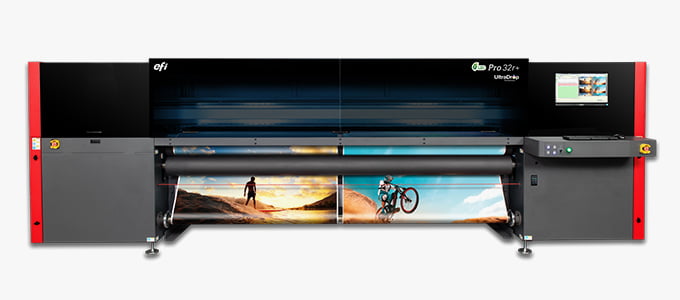

The answer here unfortunately is – it depends. In the case of EFI, their new certification covers wallcoverings produced without lamination or coating.

Learn more about EFI earning a Type II certification for wallcoverings based on the Wallcovering Association W-101 standards

DreamScape tests and warrants that our TYPE II products will meet or exceed the standards set forth in the WA-101 and NSF-342.

It is impractical for a media manufacturer to test all materials in combination with every different machine and ink type. For this reason, our warranty is based on the suitability of the base wallcovering material that we sell.

Going beyond our standard warranty, DreamScape has tested several well-known OEM digital printing systems to see how they perform. We have found some that can pass, and some that do not. Not all digital inks are the same. Some have better durability characteristics than others. And even the most durable inks can vary from job to job depending on the type of print, amount of ink used, level of curing, the texture of the surface, etc.

The ability to pass depends on many factors. If you are uncertain and are required to provide a commercial product for high-traffic areas, the safe play would be to use a liquid coating, such as our DreamGuard.

Why do some companies claim that their product is the only TYPE II for digital without a topcoat?

This is misleading marketing and untrue.

They are not the ONLY, and they are not the first. The DreamScape technical team has conducted many tests throughout the years and can refute this claim quite easily with passing results from our own products.

At DreamScape, we go the extra distance that others don’t.

The battery of tests involved in WA-101 is time consuming, rigorous, and very expensive. Very few digital printing companies have gone to the added expense of testing their own products.

If you require test results for your business, you should contact DreamScape tech support to discuss some available options.